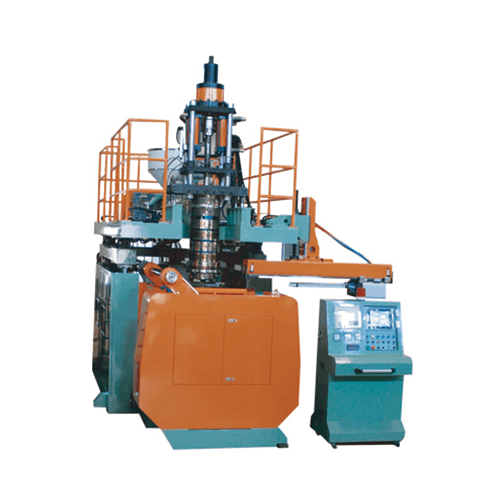

Large Blow Molding Machine

Categories : Horizontal Blow Molding Machines

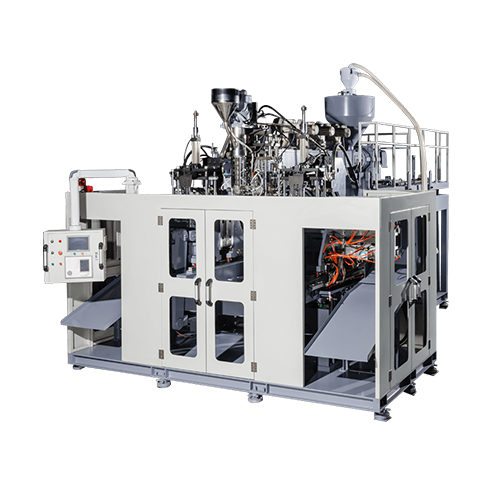

Large –Accumulator Die Head Type Blow Molding Machine These series models are suitable for productions ranging from 30L up to 130L whether for barrels, pallets, toys, water storage tanks, floats, automobile parts, and narrow or full open mouth drums applications. This machine is suitable for blowing irregular-shaped plastic products. Applications of a large accumulator blow molding machine include the following: Barrels 2-mouth jerry cans Toys Water storage tanks/ PC water jugs Paddle wheel aerator floats Air duct and other automobile parts Baby safety seats Cooler box/ice bucket Sports equipment Narrow mouth and full open mouth drums For certain products, we have developed a high-speed model of this series for customers that need a high production output.

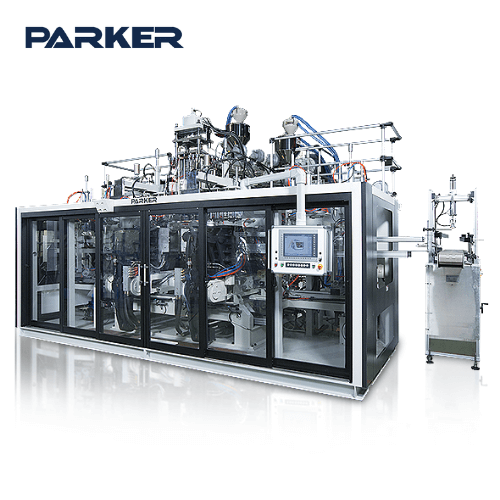

Automatic Blow Molding machine-I Series

Categories : Automatic Blow Molding Machines

Full Shine's I Series Blow Molding Machines are suitable for producing large and various plastic products, such as tool boxes, water tanks, beer drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. These machines are with lateral take-out mechanism. Machine frame and die head are movable for replacing molds easily.

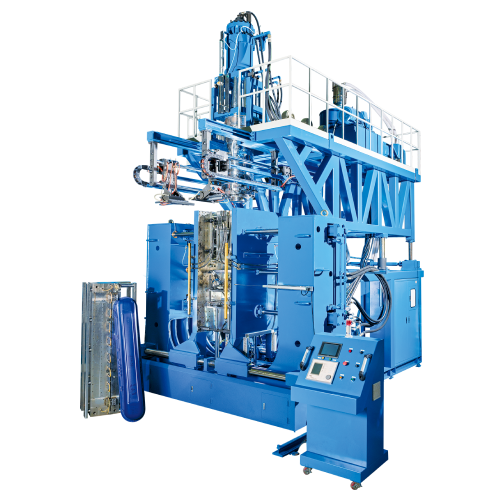

Automatic-Blow-Molding-machine-L Series

Categories : Automatic Blow Molding Machines

Full Shine's L Series Blow Molding Machines are suitable for producing big and large containers, such as water tanks, chemical drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. Mold carriages are perpendicular and easy for producing different-shaped products.

Medium Co-extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C is the most popular choice for the edible oil export countries, production ranges from 5L to 30L jerry can. The outer and inner layer composed of 15%-20% virgin material and master batches. The middle layer can put around 60%-70% cost effective regrind material and also can add CaCo3 (no more than 30%), which can reduce cost down to 10-12% material cost. By contrast, the single layer jerry can only add around 5%-7% CaCo3 which has no evident improvement over material savings. Chen Way CWM

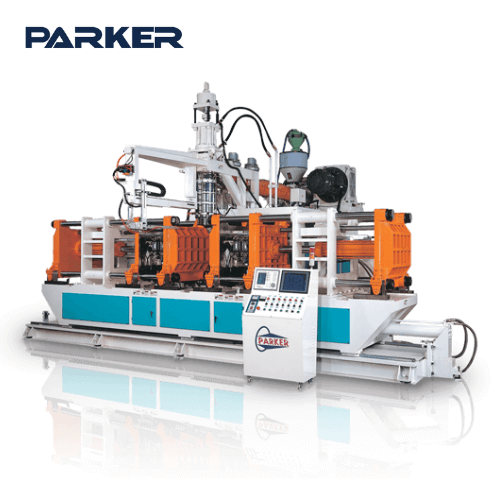

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapted for small or large-scale productions. Products that are commonly manufactured by medium continuous blow molding machines include: 20/25L jerry cans 10/20L inner thread jerry cans Diamond-shaped jerry cans Round jerry cans Water tanks With applications for edible oil, lubrication oil, electronic, agriculture, and chemical liquids, this jerry can making machine is also available as a single or double station machine, for multi-layers, multi-cavities, or even multi-color productions.

Rotary Cutter For Wide Neck Drum

Categories : Cutting Machines

-Rotary Cutter-For Open Top/Wide Neck Drum. -Increases the Production Quality by Automatically cutting the drum's neck.